Here’s a brief summary of why my bondtainer is structurally sound, in the form of answers to a couple questions raised by smart people. Thanks in particular youngest brother🙂

Won’t the bottom container collapse where you’ve cut holes in it because of the weight of the 40′ container?

This was my biggest concern. Applying Euler’s column formula for the 1.5″ square tube with .125″ walls, I get a strength of ~5.5 kips (5,500pounds force) per column (not accounting for my ~4 supports along the height of the column in addition to the ends):

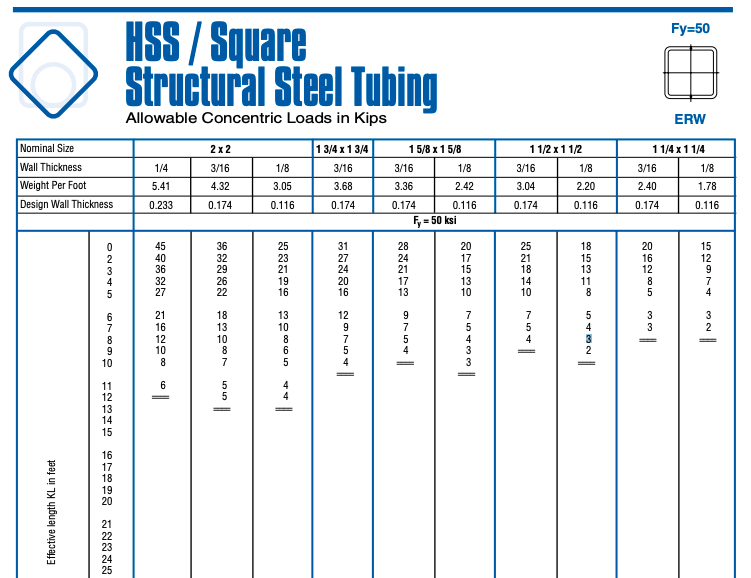

Checking with these tables, specifically this chart:

I get 3 kips. This translates to a safety factor of ~1.8 vs. my math, confirming my calculation isn’t in crazy town. Obviously this isn’t the only support for the 40′ container, and the container’s weight isn’t the only force. Coupled with the other metal of the 20′ to which these 4 columns are welded and the role I guesstimate they play in strengthening my support for the 40′, I feel very good about the 20′ container’s ability to avoid pancaking.

Are the tiny poles you’re planning to support the ends of the 40′ thick enough?

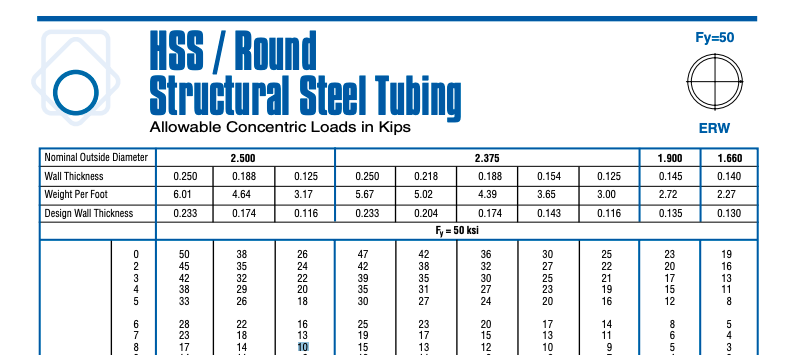

Yes:) Emboldened by the rough agreement between reference table and my math above, I’m confident the 2″ tube with .125″ walls on the door side is good 10 kips and each of the 1.75″x.125″ tubes is good to 3 kips:

I’ll probably fill all 3 with cement after a brief google wormhole into Concrete-Filled Steel Tube (CFST) construction. Also, one end pushing downward means at least some force upward on the other end (and the welds between the 2 containers…

What about the cement?

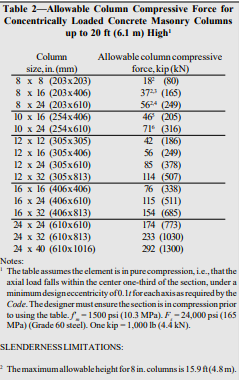

For the 20′ container’s footings, I just trusted Betin (a local builder); this is the part that made me the most nervous by far. Not that I don’t trust him: more that concrete is the only major area of this project so far both where I’m deferring to an “expert” and inexperienced personally. Then, I found this guide to concrete column design. Check out this table:

Now, I feel way better: the footings below the “tiny” poles will be 8″ diameter with 4 sticks of rebar. These are rated for 18 kips (18,000 pounds of force) each up to 15′ tall. Turns out there are strong reasons so much of the world is made from concrete + rebar…

There’s a lot of wind in La Ventana. Won’t this blow over?

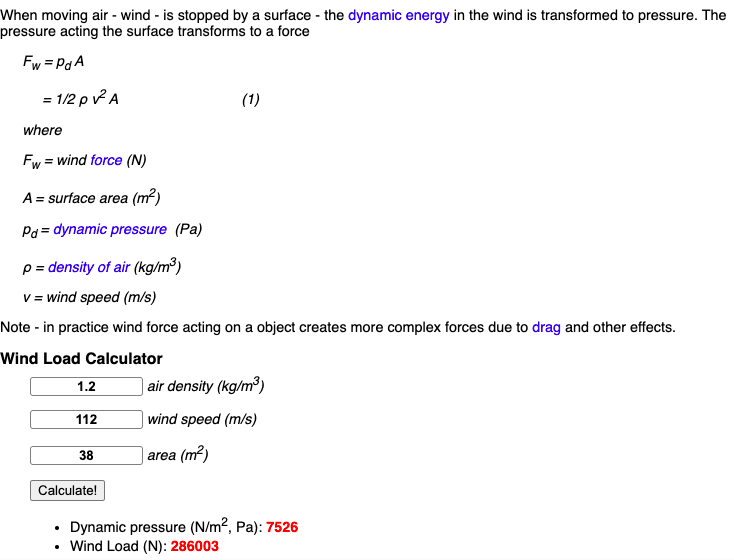

Using 250mph (~highest wind speeds recorded) and assuming wind directly perpendicular to my greatest elevation in any one direction (8.5’x40’+8.5’x20′), convenient calculator says I’m exposed to ~64,300 pounds force of wind:

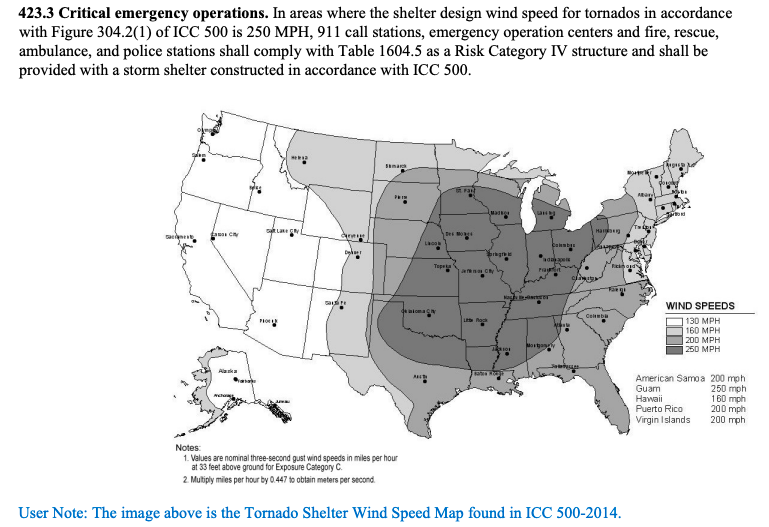

With a structure where the metal alone weighs over 12,00 pounds, ‘hurricane shutters’ that are probably thick enough to stop a 22-caliber bullet, and fig fat cement foundations, I probably qualify as a tornado shelter according to this FEMA document:

Major stuff I’ve missed? Let me know and I’ll at least think about thinking about it;)

And now, a break for a week to hang out in normal(ish) houses with mi familia in Seattle! I’m excite about everything except for the weather and location. At least 30F colder and 100% less beach than I’d like;)